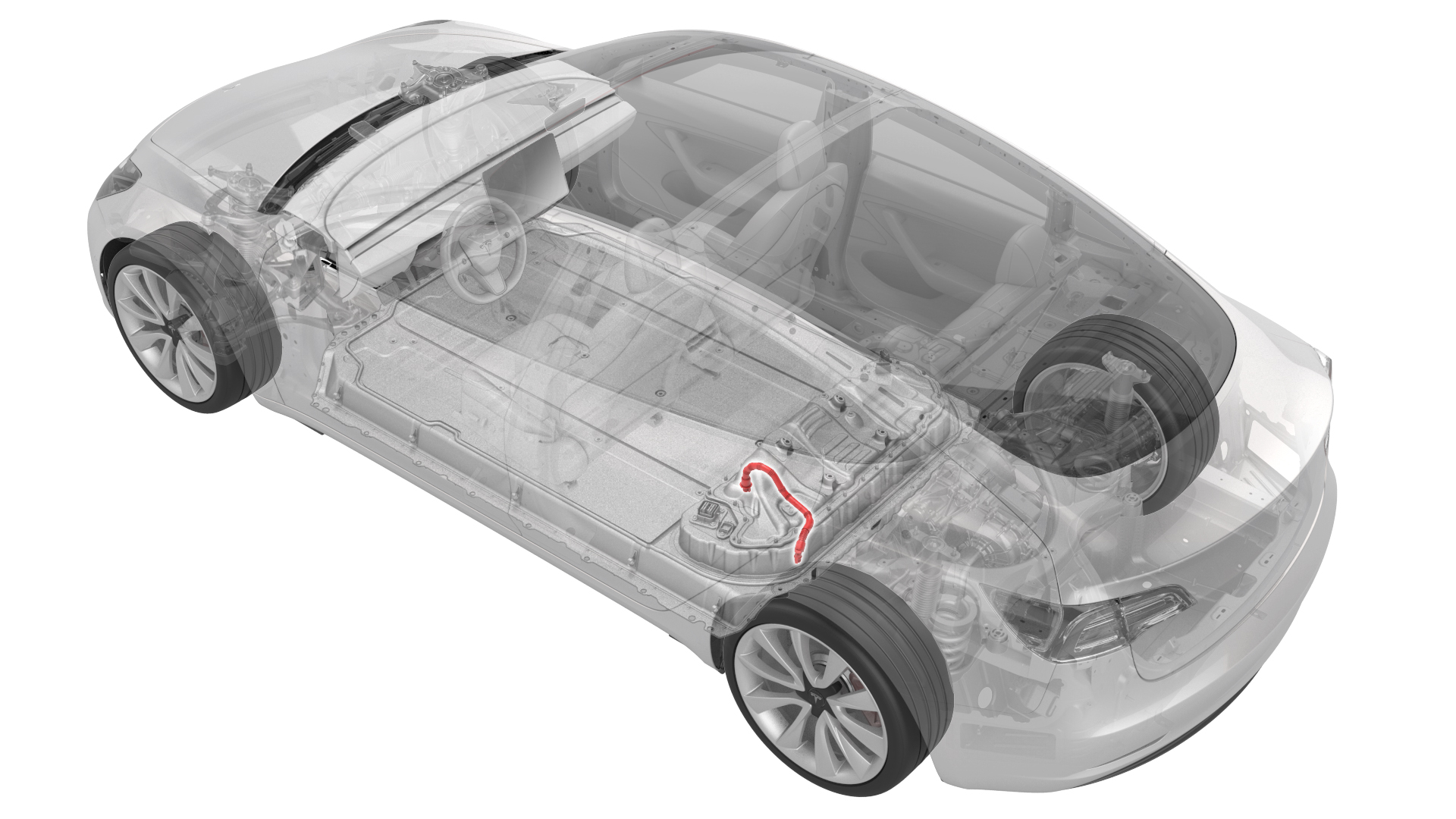

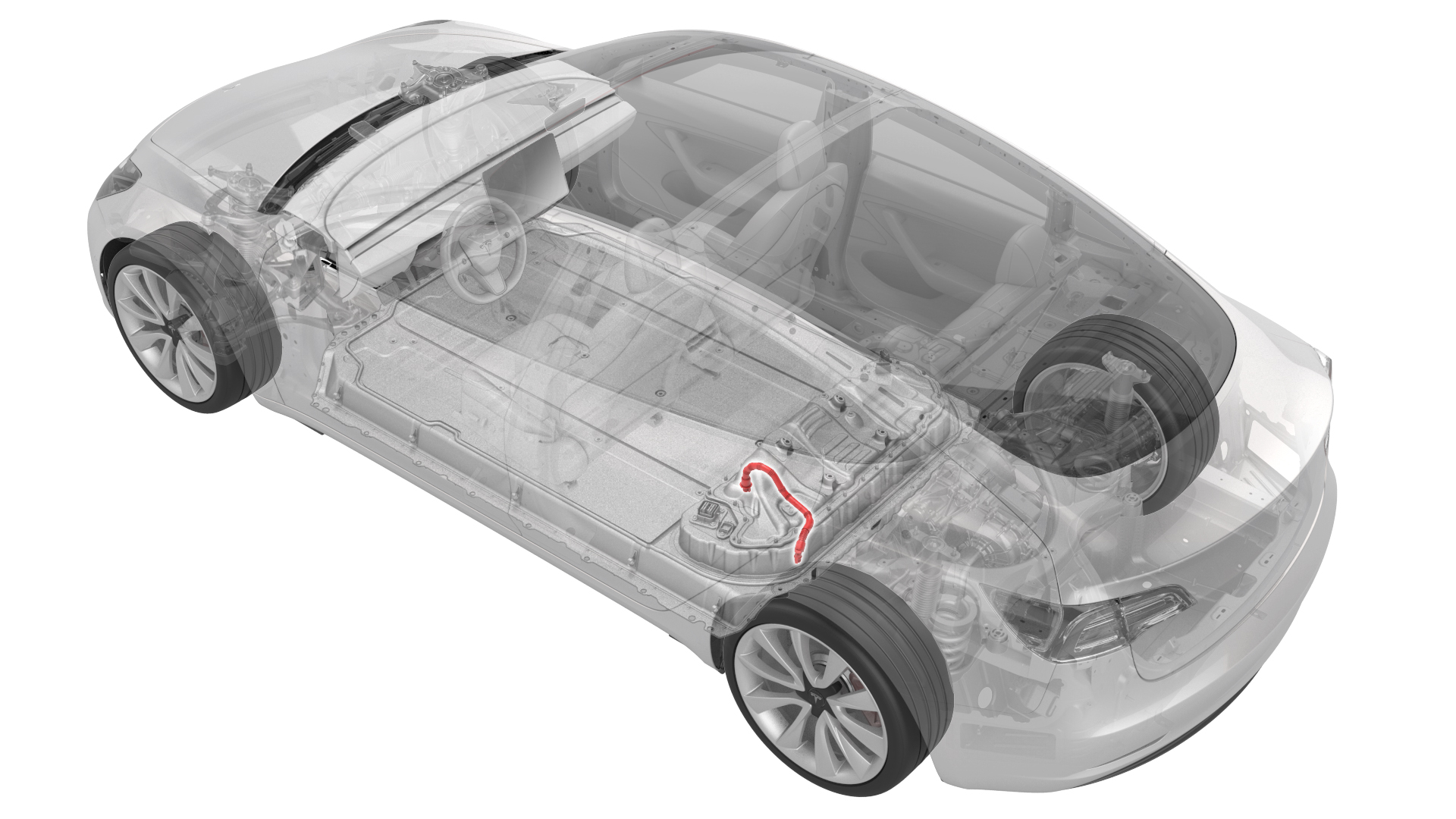

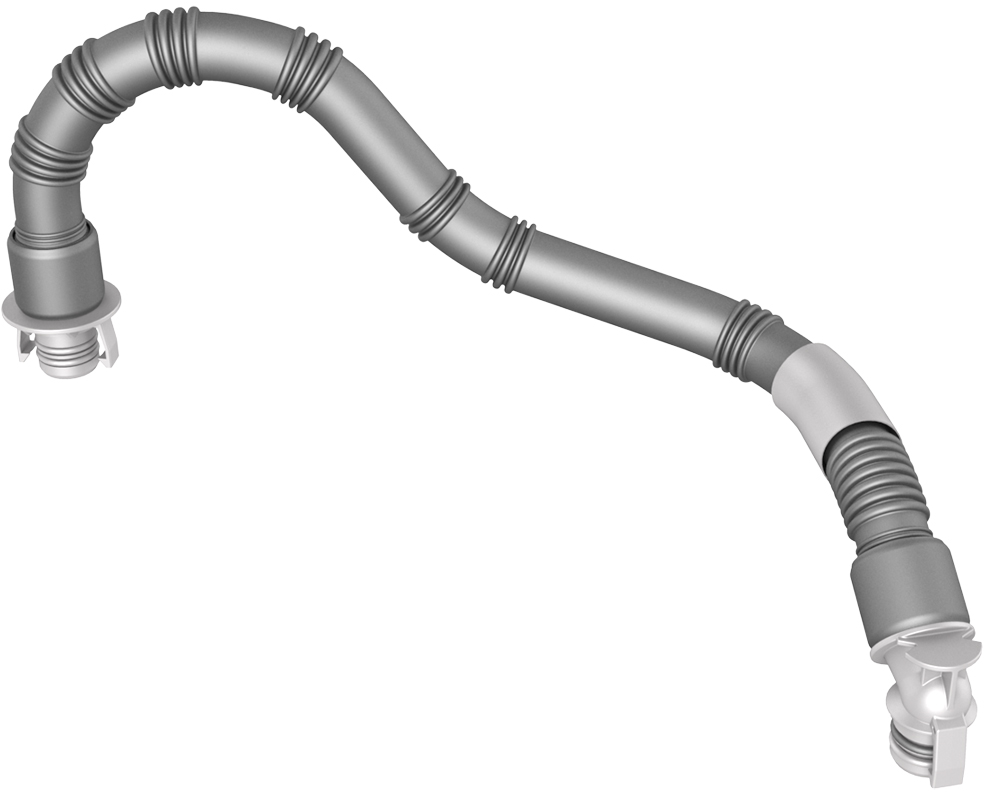

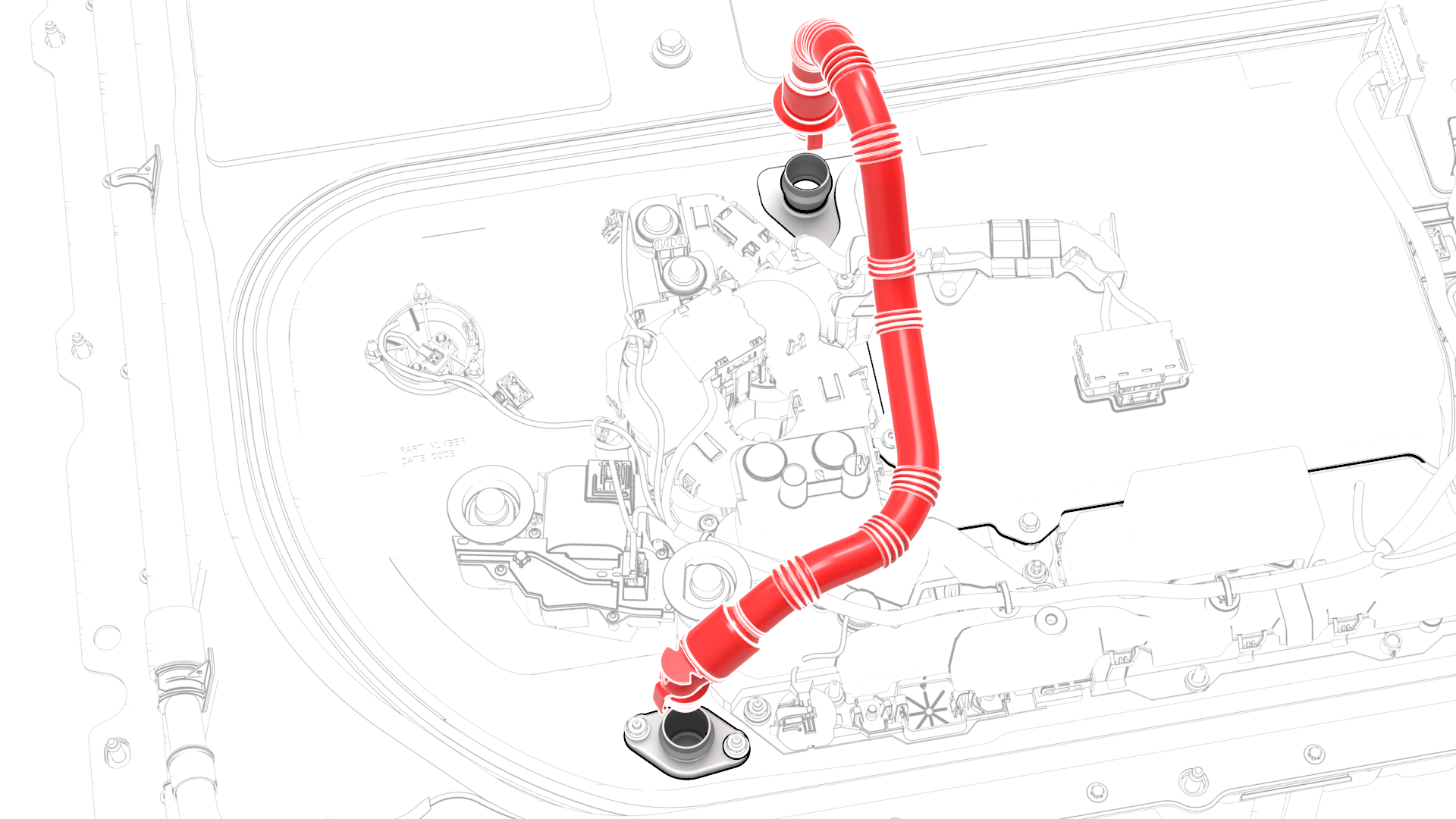

Tube - Output - Coolant - Power Conversion System (Remove and Replace)

Correction code 16202202 16202202

- 1111868-00-B Connector Removal, Coolant, PCS, M3

- 1135762-00-AKit, Svc Plug, Cooling Hose, Model 3

SPECIAL TOOLS

Connector Removal, Coolant, PCS, M3 (1111868-00-B) |

Kit, Svc Plug, Cooling Hose, Model 3 (1135762-00-A) |

Warning:

Warning:

Only technicians who have been trained in High Voltage Awareness are permitted to perform this procedure. Proper personal protective equipment (PPE) and insulating HV gloves with a minimum rating of class 0 (1000V) must be worn at all times a high voltage cable, busbar, or fitting is handled. Refer to Tech Note TN-15-92-003, "High Voltage Awareness Care Points" for additional safety information.

Remove

| 1 | Drain the coolant from the power conversion system. See Penthouse Coolant (Drain and Refill). | ||

| 2 | Remove the HV battery negative contactor. See Contactor - Negative - HV Battery (Remove and Replace). | ||

| 3 | Cut a slit halfway through 2 absorbent pads and surround each coolant output tube fitting with a pad. | ||

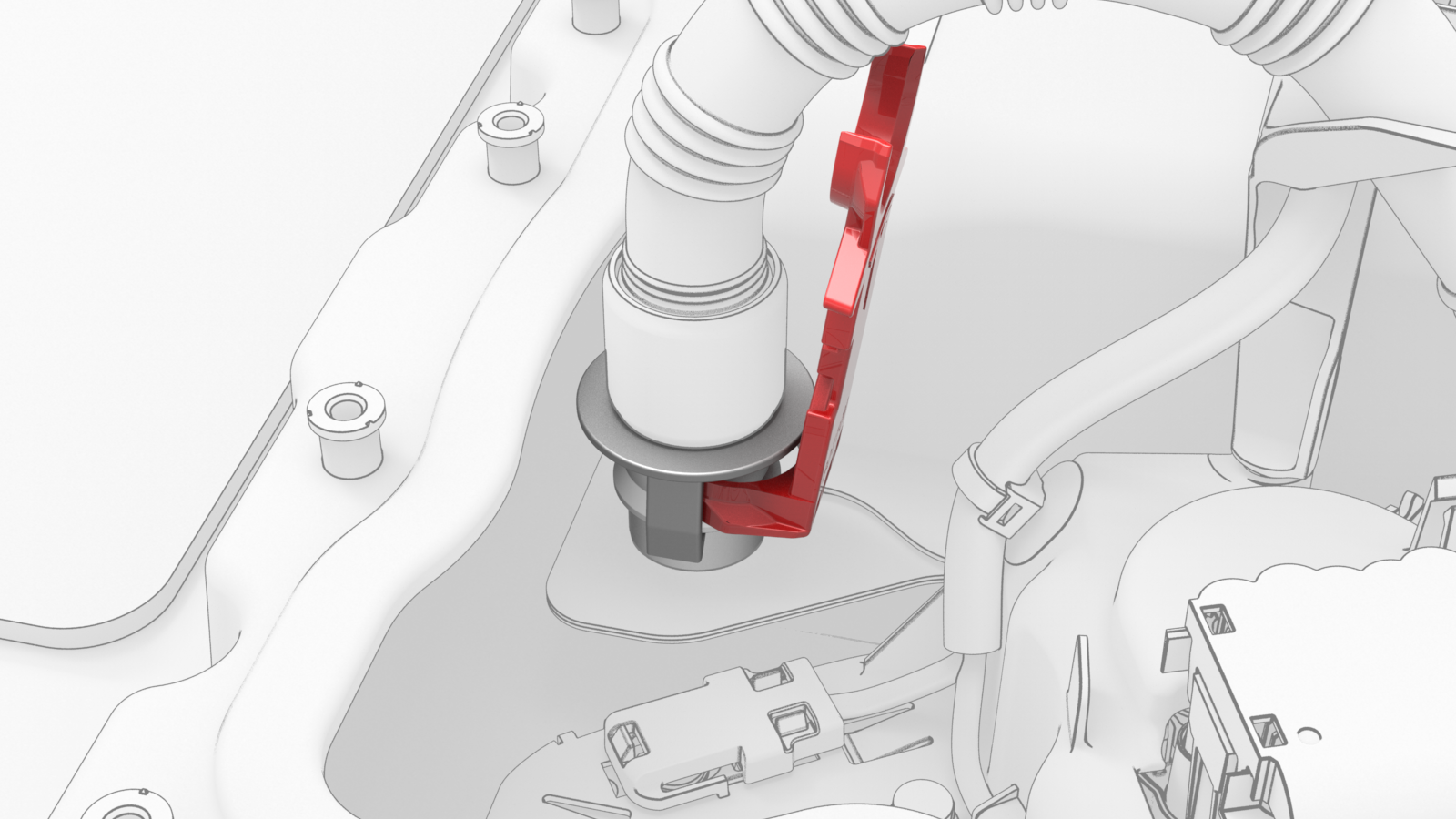

Example of Coolant Connector Removal Tool Use

| 4 | Use the coolant connector removal tool to spread the tube fitting clips wider than the barb on the power conversion system. | |

| 5 | Pull up on the tool and the tube fitting together to disconnect the fitting from the power conversion system. | ||

| 6 | Repeat step 4 and step 5 for the other tube fitting at the battery flange. | ||

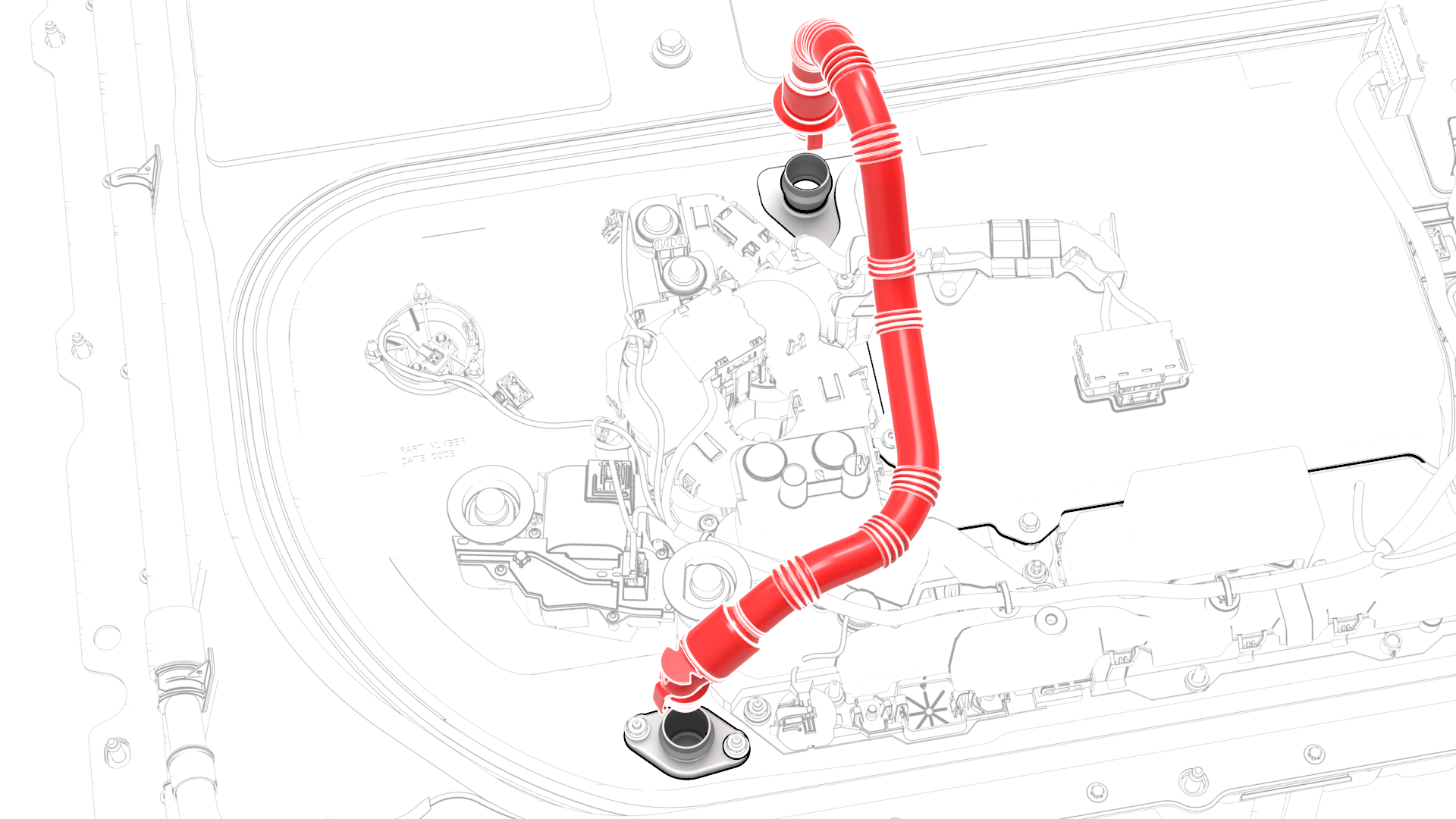

| 7 | Release the clip that attaches the tube to the HV battery AC inlet harness, and remove the tube from the vehicle. | |

| 8 | Install plugs into the power conversion system and the battery flange. | ||

| 9 | Wipe up any spilled coolant. Caution: Spilled coolant can create an electrical path.

|

Install

| 1 | Wipe up any spilled coolant. Caution: Spilled coolant can create an electrical path.

| ||

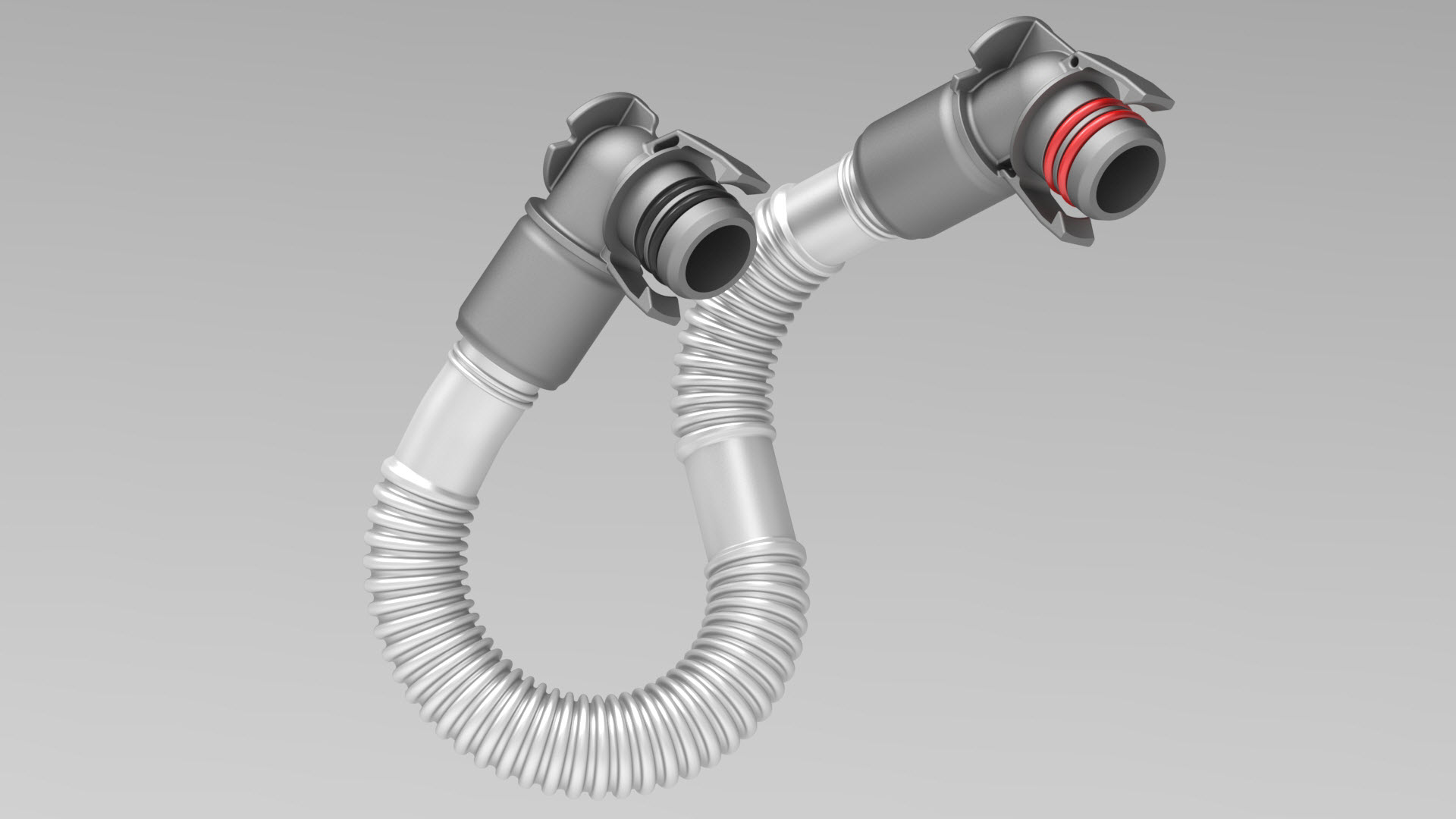

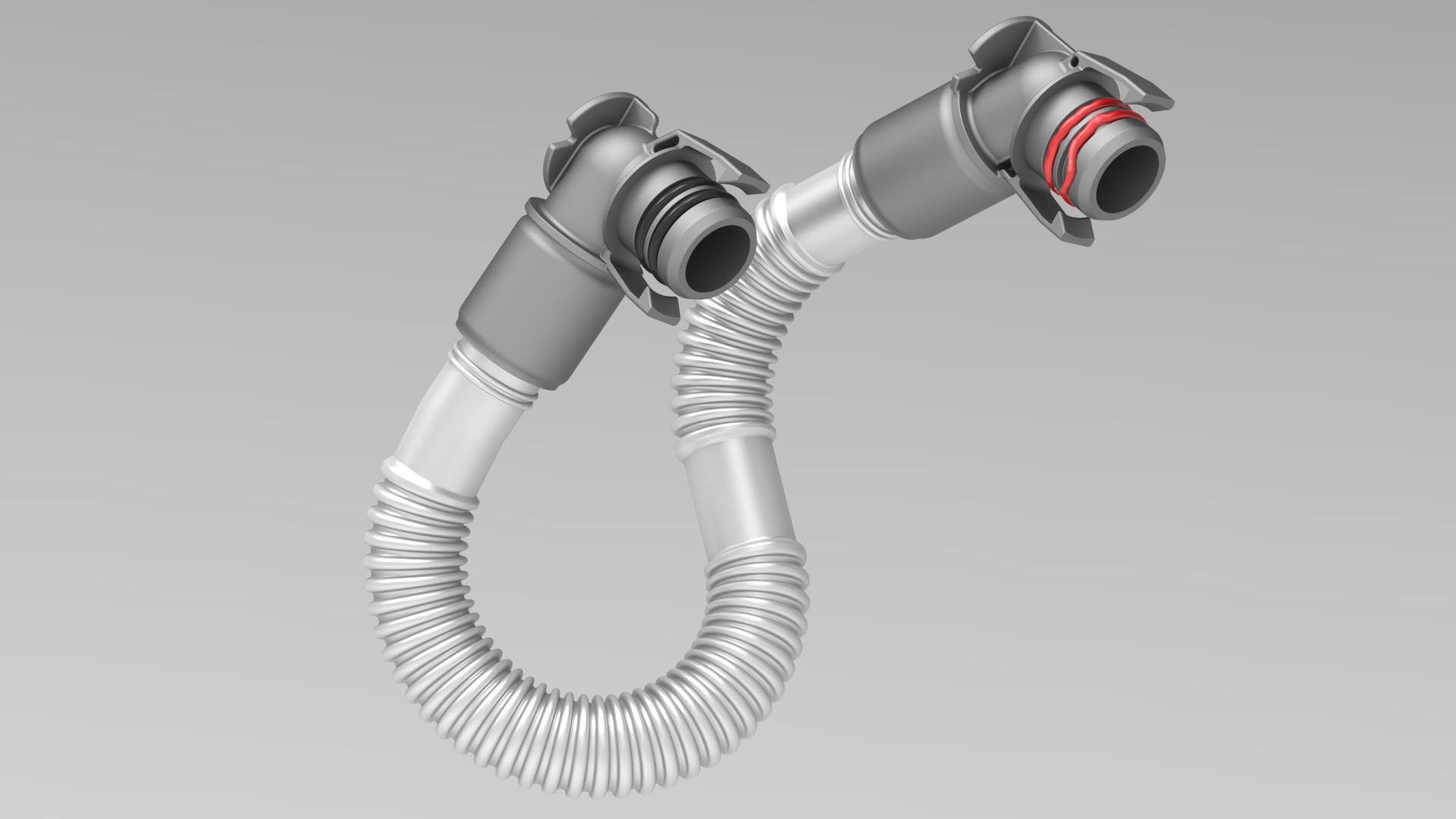

O-rings in good condition  O-ring in poor condition  | 2 | Make sure that the o-rings are not damaged and that they are properly seated in the connector groove prior to inserting the tube into the power conversion system. Replace components as necessary. | |

| 3 | Lubricate the coolant output tube o-rings with Silaramic lubricant. | ||

| 4 | Remove the plugs from the power conversion system and the battery flange. | ||

| 5 | Install the coolant output tube into the power conversion system and the battery flange. | |

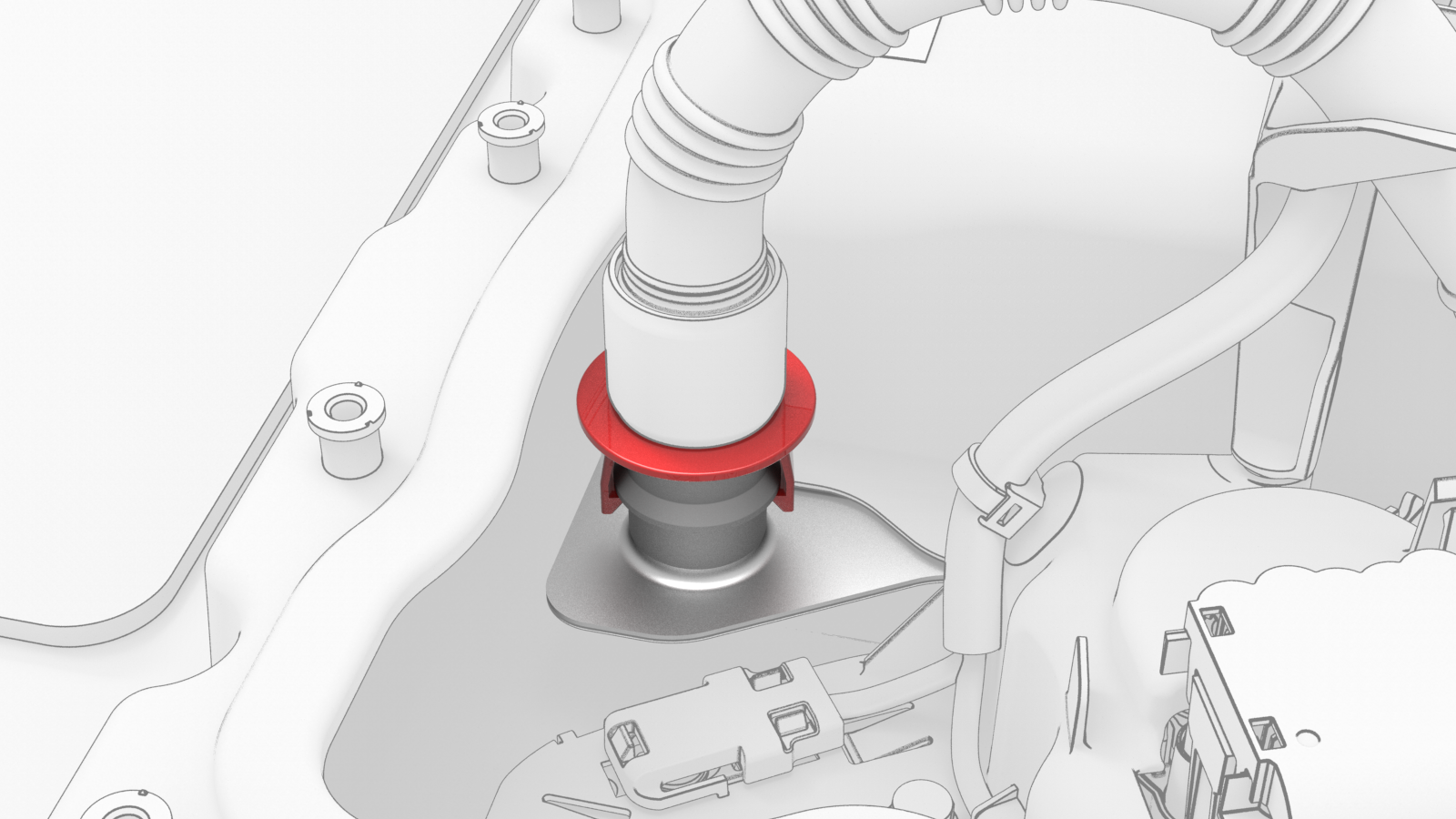

Example of a Secure Connection

| 6 | Firmly press down on the tube fittings, to make sure that the fittings are securely connected. Caution: Verify that both clips have fully engaged the barb on the power conversion system and battery flange, and then pull up on the fittings to check retention.

| |

| 7 | Remove the absorbent pads from around the coolant output tube fittings, and wipe up any spilled coolant. Caution: Spilled coolant can create an electrical path.

| ||

| 8 | Fasten the clip that attaches the tube to the HV battery AC inlet harness. | ||

| 9 | Perform a penthouse coolant leak test. See Penthouse Coolant Leak Test. | ||

| 10 | Connect the 12V auxiliary battery negative terminal only. Torque 6 Nm  Caution: Do not follow the procedure to connect 12V power at this time.

| ||

| 11 | Connect a 12V charger to the 12V auxiliary battery terminals. | ||

| 12 | Refill the coolant. See Penthouse Coolant (Drain and Refill). | ||

| 13 | On the touchscreen, touch . | ||

| 14 | Disconnect the 12V charger from the 12V auxiliary battery terminals. | ||

| 15 | Disconnect the 12V auxiliary battery negative terminal. | ||

| 16 | Install the HV battery negative contactor. See Contactor - Negative - HV Battery (Remove and Replace). |